Tennis is a popular sport that requires a few essential pieces of equipment, and one of them is the tennis ball.

Tennis balls are small, lightweight, and come in bright yellow. They are used in every tennis match and can be found in almost every sports store.

But have you ever wondered what tennis balls are made of?

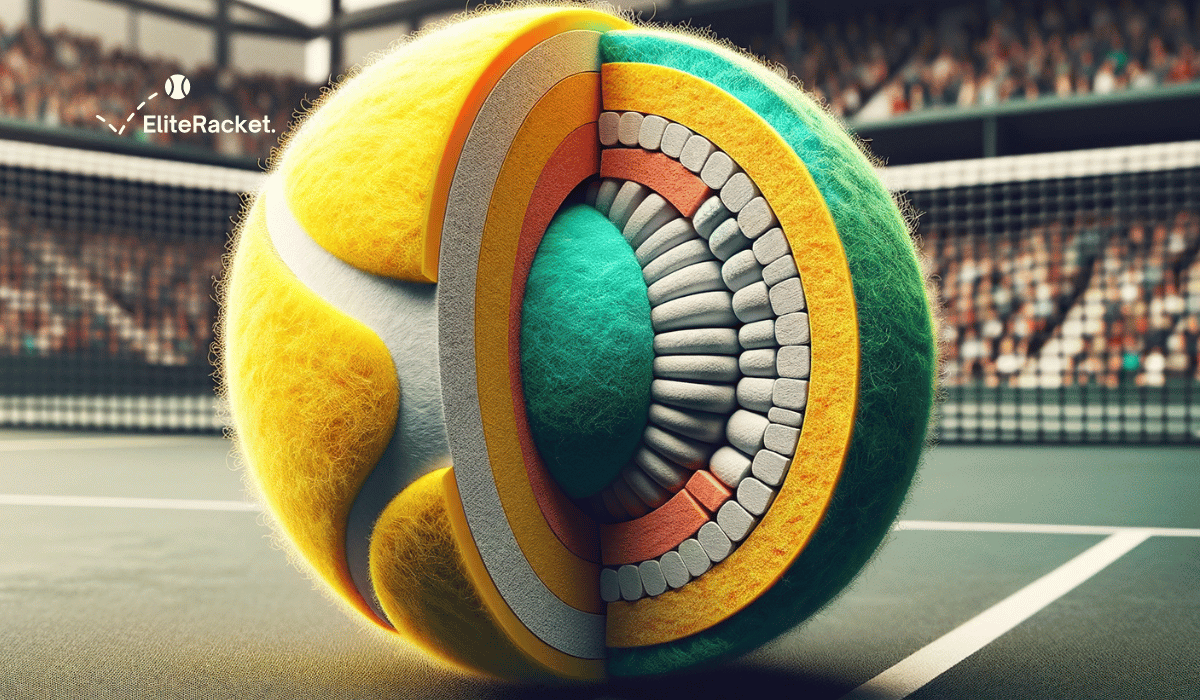

The materials used in tennis balls are quite simple. Tennis balls are made of a rubber core, which is covered in a layer of felt made from nylon or wool. The felt is then coated with a thin layer of rubber to protect it from wear and tear.

The rubber core is what gives the ball its bounce, and the felt is what helps the ball grip the court.

Key Takeaways

- Tennis balls are made of a rubber core and a felt covering.

- The rubber core gives the ball its bounce, and the felt helps it grip the court.

- Tennis balls are covered in a thin layer of rubber to protect the felt from wear and tear.

Materials Used in Tennis Balls

Tennis balls are made of a combination of materials that provide the desired characteristics of the ball such as bounce, durability, and aerodynamics.

The primary materials used in tennis balls are rubber and felt, although some high-altitude tennis balls may contain different materials to adjust for the thinner air at higher elevations.

Rubber Core

The rubber core is the most important part of the tennis ball as it provides the bounce and responsiveness that players rely on during a match.

The core is typically made of a pressurized rubber compound that is designed to retain its shape and pressure over time.

The International Tennis Federation (ITF) specifies that the diameter of a tennis ball must be between 2.57 inches and 2.70 inches and the weight must be between 1.98 ounces and 2.10 ounces.

Felt Covering

The felt covering of a tennis ball is responsible for the ball’s aerodynamics and durability.

The felt is typically made of a combination of wool and nylon fibers that are tightly woven together to create a durable outer layer. The felt helps to reduce aerodynamic drag, which allows the ball to travel through the air more efficiently.

The ITF specifies that the felt must be white or yellow and have a nap that is no longer than 1/8 inch.

High-Altitude Materials

High-altitude tennis balls are designed to adjust for the thinner air at higher elevations. These balls typically contain less pressurized gas in the rubber core and may have different felt materials to adjust for the lower air resistance.

High-altitude tennis balls are designed to bounce lower and move slower through the air to compensate for the thinner air, which can cause regular tennis balls to fly too far and too fast.

In conclusion, tennis balls are made of a combination of rubber and felt materials that provide the desired characteristics of the ball.

The rubber core provides bounce and responsiveness, while the felt covering provides aerodynamics and durability.

High-altitude tennis balls may contain different materials to adjust for the thinner air at higher elevations.

Manufacturing Process

Tennis balls are made of a rubber core covered by a layer of felt.

The manufacturing process is complex and requires several steps to ensure the quality of the final product.

Core Production

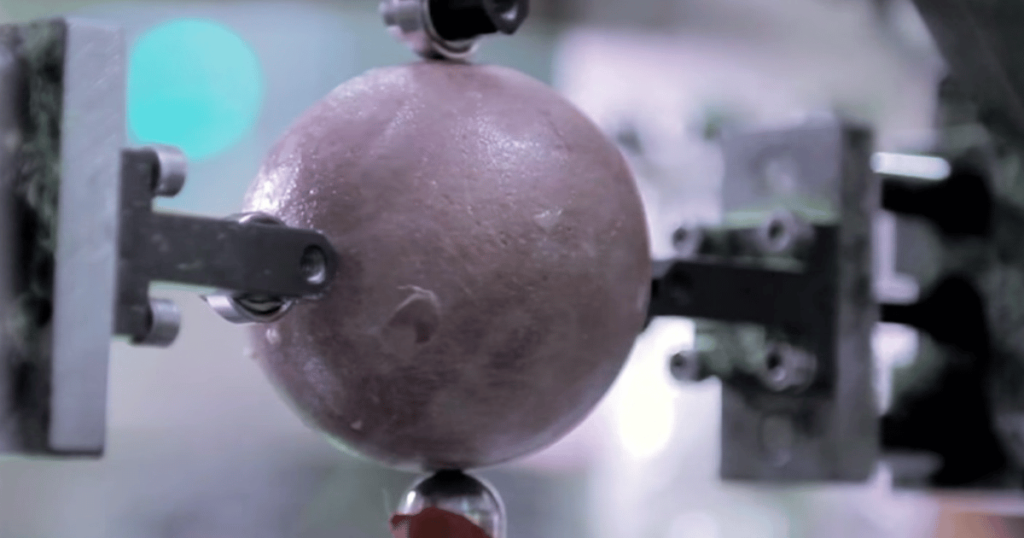

The first step in the manufacturing process is the production of the rubber core. The raw rubber comes into the factory in bales of 70-250 lbs. The rubber is then mixed with various chemicals and heated to form a liquid solution.

This solution is then cooled and cut into small pellets. The pellets are then molded into a hollow sphere using a hydraulic press.

The hollow sphere is then vulcanized, a process that involves heating the rubber to a high temperature to make it more elastic.

Felt Application

After the core is produced, the felt is applied to the surface. The felt is made of woven wool and is cut into small pieces.

The pieces are then glued to the surface of the rubber core using a special adhesive.

The felt is then pressed onto the core using a machine that applies pressure evenly across the surface.

Final Assembly

The final step in the manufacturing process is the assembly of the tennis ball. The two halves of the ball are brought together and welded using a high-frequency welding machine.

The ball is then inspected for defects, and any imperfect balls are discarded. The final product is then packaged and shipped to stores and distributors.

In conclusion, the manufacturing process of tennis balls is a complex and precise process that involves several steps to ensure the quality of the final product.

The core is produced using a mixture of rubber and chemicals, the felt is applied to the surface using a special adhesive, and the final product is assembled using a high-frequency welding machine.

Types of Tennis Balls

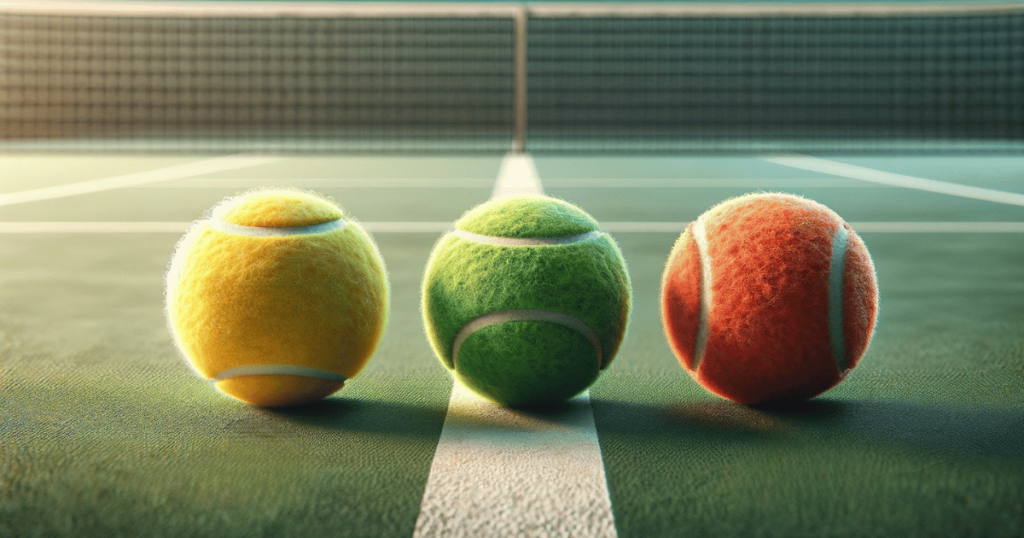

Professional Standard

Professional standard tennis balls are used in tournaments and professional matches. These balls are made from a rubber compound with felt covering them.

The official diameter of the ball falls between 2.57 inches and 2.70 inches, and the mass can be anywhere from 1.98 ounces to 2.10 ounces.

The rubber used in professional standard tennis balls is similar to that used in car tires, and the felt is usually made from wool or nylon. These balls are pressurized to give them their bounce and are replaced after each set.

Recreational Play

Recreational play tennis balls are used for casual games and practice sessions. These balls are similar to professional standard balls, but they are not pressurized.

This means that they do not bounce as high as pressurized balls and they lose their bounce more quickly.

Recreational play tennis balls are usually cheaper than professional standard balls and are a good choice for beginners and those who want to practice their game.

Non-Pressurized Variants

Non-pressurized tennis balls are a variant of recreational play tennis balls. These balls are made from a solid rubber core with a felt covering.

They do not have the same bounce as pressurized balls and are often used for training and practice sessions.

Non-pressurized tennis balls are cheaper than pressurized balls and are a good choice for those who want to practice their game without spending a lot of money.

Overall, there are different types of tennis balls available for different levels of play. Whether you are a beginner or a professional player, there is a tennis ball that will suit your needs.

Quality and Regulation Standards

Tennis balls are manufactured to meet certain quality and regulation standards that ensure they perform consistently and safely.

These standards are set by the International Tennis Federation (ITF), which is the governing body of tennis worldwide.

International Tennis Federation Specifications

According to the ITF, tennis balls must have a diameter of 6.54-6.86 cm (2.57-2.70 in) and weigh between 56.0-59.4 g (1.98-2.10 oz). They must also have a pressure of 6.5-9.5 kPa (0.95-1.38 psi).

These specifications ensure that tennis balls are of a consistent size, weight, and pressure, which helps players to develop their skills and play the game effectively.

In addition to size, weight, and pressure, the ITF also regulates the color of tennis balls. Tennis balls come in different colors, such as yellow and white, and are color-coded to indicate the type of court surface they are suitable for.

For example, yellow balls are used on hard and grass courts, while white balls are used on clay courts.

Regular Testing Procedures

To ensure that tennis balls meet the ITF specifications, they are subject to regular testing procedures. Manufacturers must test their tennis balls for size, weight, and pressure, and submit them to the ITF for approval.

Once approved, the tennis balls are marked with the ITF logo, which indicates that they meet the required standards.

Furthermore, the ITF regularly tests tennis balls from different manufacturers to ensure that they continue to meet the required standards. If a tennis ball fails to meet the standards, it is not approved for use in tournaments and competitions.

In conclusion, the ITF sets strict regulations and quality standards for tennis balls to ensure that they perform consistently and safely.

Manufacturers must adhere to these standards and subject their tennis balls to regular testing procedures to ensure that they meet the required specifications.

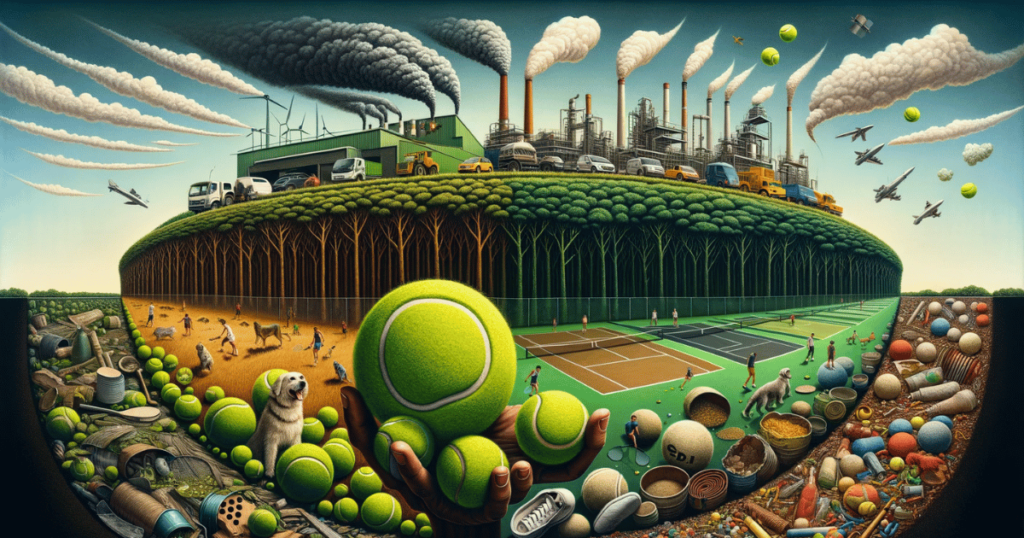

Environmental Considerations

Tennis balls, like any other product, have environmental impacts. The production and disposal of tennis balls have raised concerns about sustainability and waste management.

In this section, we will explore the environmental considerations associated with tennis balls.

Sustainability Efforts

The production of tennis balls requires natural and synthetic rubber, which is a resource-intensive process. The rubber plantations require deforestation, which can lead to habitat destruction and biodiversity loss.

Furthermore, the manufacturing process involves the use of chemicals, which can be harmful to the environment.

However, many manufacturers are taking steps to reduce their environmental footprint. For example, some companies are using recycled rubber in their tennis balls, reducing the need for new rubber.

Additionally, some manufacturers are using more sustainable materials, such as natural rubber from sustainable sources.

Recycling and Disposal

Tennis balls have a limited lifespan and eventually lose their bounce, making them unusable. The disposal of tennis balls has raised concerns about waste management. Tennis balls are not biodegradable, and when they end up in landfills, they take up space and do not decompose.

However, there are efforts to recycle tennis balls. Some organizations collect used tennis balls and recycle them into new products such as playground surfaces, pet toys, and even shoes.

Additionally, some companies have developed recycling programs to collect used tennis balls and recycle them into new tennis balls.

In conclusion, tennis balls have environmental impacts that need to be addressed. However, manufacturers and organizations are taking steps to reduce their environmental footprint and recycle used tennis balls.

By being mindful of the environmental considerations associated with tennis balls, we can work towards a more sustainable future.

Frequently Asked Questions

What materials are used to manufacture the outer surface of tennis balls?

The outer surface of a tennis ball is made of felt, which is a type of fabric that is typically composed of wool and nylon.

The wool provides the ball with its fuzzy texture, which helps to create the characteristic bounce and spin.

The nylon fibers add strength and durability to the fabric, allowing the tennis ball to withstand the rigors of play.

The felt is then treated with a special adhesive to help it adhere to the rubber core of the ball.

How has the composition of tennis balls evolved since their inception?

Tennis balls have come a long way since their inception in the 19th century. Originally, tennis balls were made of leather and stuffed with hair or wool.

Later, rubber was introduced as a core material, and the outer surface was made of flannel.

In the 20th century, the use of synthetic materials such as nylon and polyester became more common, and the manufacturing process became more sophisticated.

Can you explain the chemical composition that gives tennis balls their unique characteristics?

The chemical composition of tennis balls is complex and varies depending on the manufacturer. However, all tennis balls are made of a combination of rubber, felt, and other materials to create a bouncing and firm ball.

The inner core of the ball is usually a rubber-like compound that is designed to provide the ball with its bounce and resilience.

The outer surface of the ball is composed of two pieces of felt which are sewn together and covered with a thin layer of rubber.

What type of polymer is used in the core construction of tennis balls?

The core of a tennis ball is typically made of a polymer material that is designed to provide the ball with its bounce and resilience.

The exact composition of the polymer varies depending on the manufacturer, but it is typically a blend of natural and synthetic rubbers.

How are modern tennis balls produced, from core to cover?

Modern tennis balls are produced using a complex manufacturing process that involves several stages.

First, the rubber core is molded into shape and then coated with a layer of adhesive.

Next, the felt covering is wrapped around the core and sewn together. Finally, the ball is coated with a layer of rubber and pressurized to create the characteristic bounce.